The process of bringing a new product to market has changed dramatically over the last decade. What once took years of research, prototyping, and manufacturing can now be done in a fraction of the time, thanks to advanced manufacturing technologies. As an entrepreneur deeply involved in product development and engineering, I’ve witnessed firsthand how innovations in manufacturing are revolutionizing industries and opening new doors for creators, businesses, and consumers alike.

The Acceleration of Product Development

Traditionally, product development was a slow and expensive process. Engineers and designers would spend months, sometimes years, refining prototypes and working through countless iterations before a product was ready for mass production. However, with the advent of digital tools, automation, and new manufacturing techniques, the time from concept to creation has drastically shortened.

Today, computer-aided design (CAD) software enables rapid prototyping and real-time adjustments, allowing for faster innovation and improved accuracy. This means that companies can move from an initial idea to a physical prototype in a matter of weeks, rather than months or years. Additionally, these digital tools minimize errors, reducing the costly trial-and-error phases that often slow down development.

3D Printing: A Game-Changer in Prototyping

One of the most significant breakthroughs in manufacturing technology is 3D printing. This technology allows for the rapid creation of prototypes and functional parts without the need for expensive molds or tooling. It has completely changed the way we approach product development, enabling businesses to test designs quickly and make adjustments without significant investment.

3D printing is also revolutionizing custom manufacturing. With traditional methods, creating a one-off product or small production run would be prohibitively expensive. Now, businesses can produce tailored solutions for specific needs, whether it’s custom medical implants, aerospace components, or consumer products designed for niche markets.

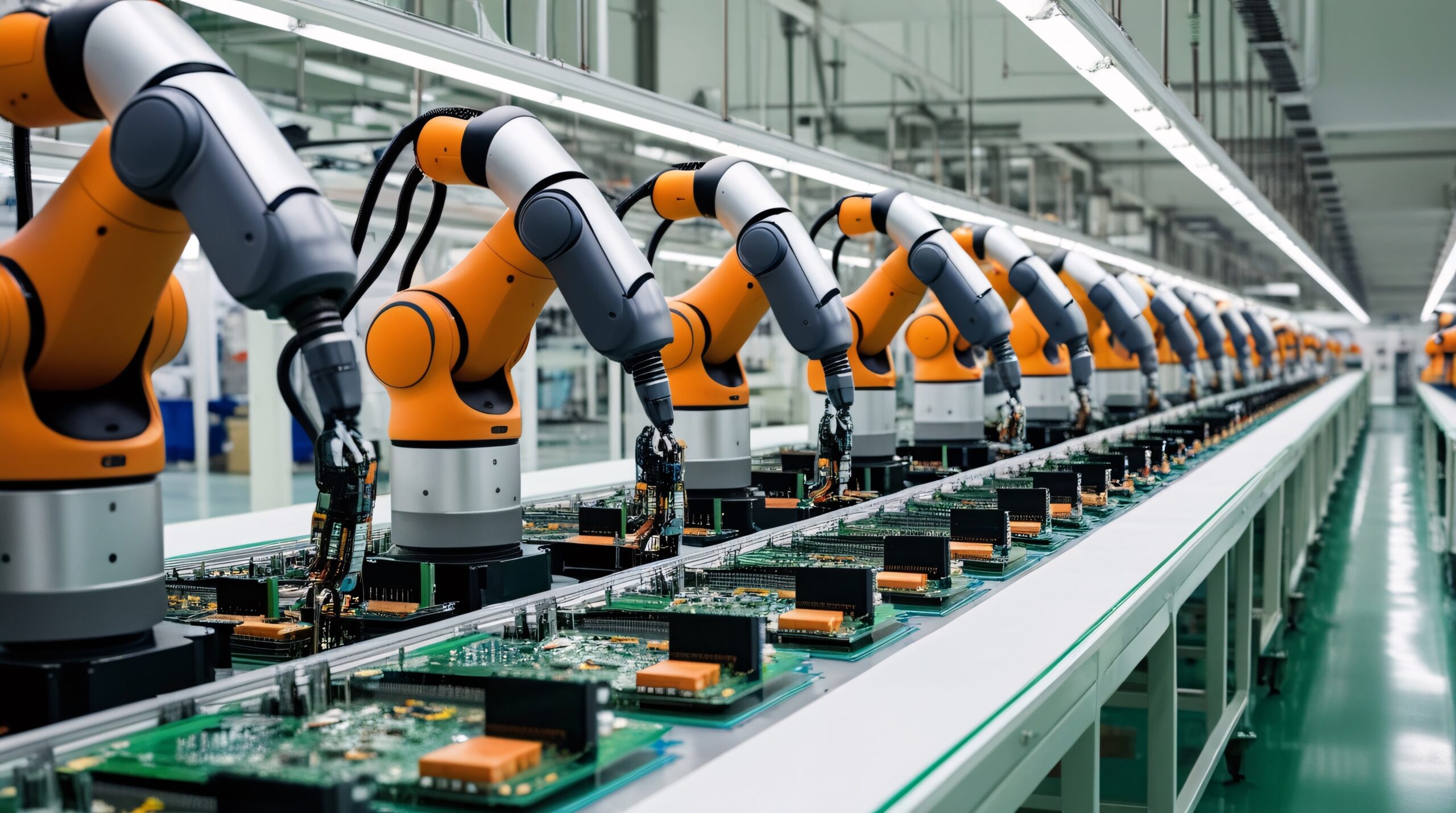

Automation and Robotics: Enhancing Precision and Efficiency

Automation has long been a driving force behind manufacturing improvements, but recent advancements in robotics and artificial intelligence have taken it to the next level. Modern robotic systems can perform complex assembly tasks with unmatched precision and speed, reducing human error and increasing efficiency.

In my own companies, we leverage automation to enhance both production quality and output. Robotic arms can handle delicate materials, ensuring consistency in manufacturing, while AI-driven analytics help optimize production schedules and minimize waste. The integration of these technologies not only improves productivity but also allows businesses to scale operations more effectively.

The Rise of Smart Materials

Another exciting area of innovation is the development of smart materials—engineered materials that have built-in capabilities to adapt to different environments or self-heal when damaged. These materials are transforming industries like aerospace, automotive, and even consumer goods.

For example, self-healing polymers and shape-memory alloys allow products to last longer and perform better under extreme conditions. In the construction industry, advanced concrete formulas with self-repairing properties are reducing maintenance costs and improving infrastructure longevity. As material science continues to evolve, we can expect even more groundbreaking applications in the coming years.

Sustainability and Green Manufacturing

With the rise of environmental awareness, sustainability has become a major focus in manufacturing. Companies are adopting greener practices, from using recycled materials to implementing energy-efficient production processes.

Advanced manufacturing techniques are making it easier to create sustainable products without compromising quality. For instance, additive manufacturing (such as 3D printing) produces less waste than traditional subtractive methods, and AI-driven production planning can optimize material usage to reduce excess.

Sustainability isn’t just about reducing waste; it’s also about creating products that have a longer lifespan and lower environmental impact. Businesses that integrate sustainable practices into their manufacturing processes are positioning themselves for long-term success while making a positive impact on the planet.

The Future of Product Development

Looking ahead, the intersection of AI, automation, and advanced materials will continue to reshape the manufacturing landscape. Companies that embrace these innovations will gain a competitive edge, bringing better products to market faster and more efficiently than ever before.

At Delco, LLC, we’re always exploring new ways to leverage advanced manufacturing technologies to push the boundaries of product development. Whether it’s through AI-powered design optimizations, the use of high-performance materials, or integrating sustainable practices, our goal is to remain at the forefront of innovation.

For entrepreneurs and businesses looking to develop new products, now is the best time to take advantage of these technological advancements. By staying informed, adapting to new trends, and investing in cutting-edge manufacturing techniques, we can continue to create products that not only meet market demands but also shape the future.

Conclusion

The evolution of manufacturing technology is making it easier, faster, and more cost-effective to bring innovative products to life. From digital design tools and 3D printing to automation, smart materials, and sustainable practices, the landscape of product development is changing at an unprecedented pace.

As someone deeply invested in this space, I’m excited about what the future holds. The possibilities for product development are endless, and those who embrace these advancements will be the ones leading the next generation of industry-changing innovations. Whether you’re an entrepreneur, an engineer, or a business owner, now is the time to leverage technology and turn your ideas into reality.